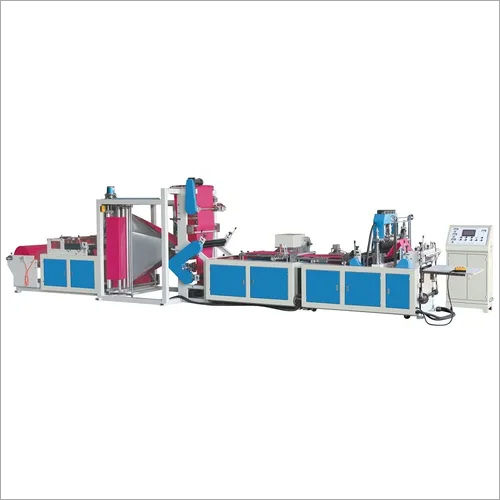

Fully Automatic Non Woven Bag Making Machine

Price 1250000 INR/ Unit

Fully Automatic Non Woven Bag Making Machine Specification

- Product Type

- Bag Machine

- General Use

- Non Woven Bag Making

- Automatic Grade

- Fully Automatic

- Drive Type

- Electric

- Bag Type

- Non Woven Bag

- Bag Length

- UP TO 580 Millimeter (mm)

- Voltage

- 220-240 Volt (v)

Fully Automatic Non Woven Bag Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Fully Automatic Non Woven Bag Making Machine

Product details

| Fabric Thickness | 100 GSM |

| Frequency | 50 Hz |

| Roller Diameter | 1000 mm |

| Bag Material | Non Woven Fabric |

| Automation Grade | Automatic |

| Country of Origin | Made in India |

| Dimension | 9300x2000x2200 mm |

| Voltage | 220 V |

| Power | 10 kW |

| Phase | Single Phase |

| Capacity | 120 Pieces Per Min |

| Model Name/Number | HBL-C700 |

| Brand | Future |

| Max Bag Width | 800 mm |

| Max Bag Length | 580 mm |

| Usage/Application | Bag Making |

Advanced Automation for Efficient Bag Production

This machine utilizes fully automatic technology to streamline the production of non woven bags. With an electric drive and customizable bag lengths up to 580 mm, users benefit from minimized labor and enhanced productivity. The automation not only accelerates manufacturing but also improves quality and consistency across batches.

Versatile Application in Indian Market

Widely adopted by exporters, importers, manufacturers, and suppliers, this machine supports the growing demand for non woven bags in India. It enables businesses to cater to diverse packaging needs, ensuring reliable supply and competitive edge in eco-friendly bag production.

FAQ's of Fully Automatic Non Woven Bag Making Machine:

Q: How does the fully automatic non woven bag making machine operate?

A: This machine employs electric drive technology and automates all stages of bag production, including feeding, stitching, and sealing. By setting desired bag parameters, users can start continuous production with minimal manual oversight.Q: What types of bags can this machine produce?

A: The machine specializes in manufacturing various sizes and styles of non woven bags, adaptable up to 580 millimeters in length, suitable for shopping, packaging, and promotional uses.Q: When is it suitable to use this machine in business operations?

A: It is ideal for high-volume production environments seeking efficient, rapid, and standardized non woven bag output. Businesses aiming to expand their eco-friendly packaging line will find it especially beneficial.Q: Where is this machine primarily utilized in India?

A: Manufacturers, suppliers, exporters, and importers across India employ this machine in their production facilities to meet domestic and international demand for non woven bags.Q: What is the process involved in making bags with this machine?

A: Once raw non woven fabric is loaded, the machine automatically feeds, shapes, stitches, and seals bags according to set specifications, delivering finished products without manual handling.Q: What are the main benefits of using a fully automatic non woven bag making machine?

A: Key advantages include increased production speed, consistent bag quality, reduced labor costs, and the ability to produce environmentally friendly packaging efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Woven Bag Making Machine Category

Non Woven Box Type Bag Making Machine

Price 1270000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Fully Automatic

Voltage : 220 Volt (v)

General Use : Bag Making

Ultrasonic Sewing Lace Machine

Price 85000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Semi Automatic

Voltage : 220 Volt (v)

General Use : Sewing Lace

Drive Type : Electric

Fully Automatic (D) (W) Cut Non Woven Bag Machine

Price 1249997.0 INR / Unit

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Drive Type : Electric

GST : 33CLRPA1089B1ZF

|

FUTURE PACKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry